RFID Textile Tracking System

RFID Application in Textile Industry

In the textile and clothing industry, RFID helps to accurately determine the types, sizes and counts of products. It has a wide range of uses, such as wholesalers, retailers, clothing service companies, companies that clean hospital gowns and sheets, or companies that clean hotel towels and sheets. In addition to all these, brand manufacturers use RFID technology to identify their original products. They follow this by sewing sewable rfid labels into their products.

Benefits of RFID in the Textile Industry

It has benefits such as increasing competition, preventing theft, special design and presentation opportunity for customers, close monitoring of products in order to eliminate problems and increasing efficiency during the transportation of products. In addition to all these, thanks to active rfid systems, productivity has increased in the merchandising sector. Data such as which product is examined for how long and whether it is received or not can be collected in this way. The detection of returned products can be detected very easily. Since data such as the sales date and price of the product can be stored on the label, all kinds of details can be accessed when the product is read into the system.

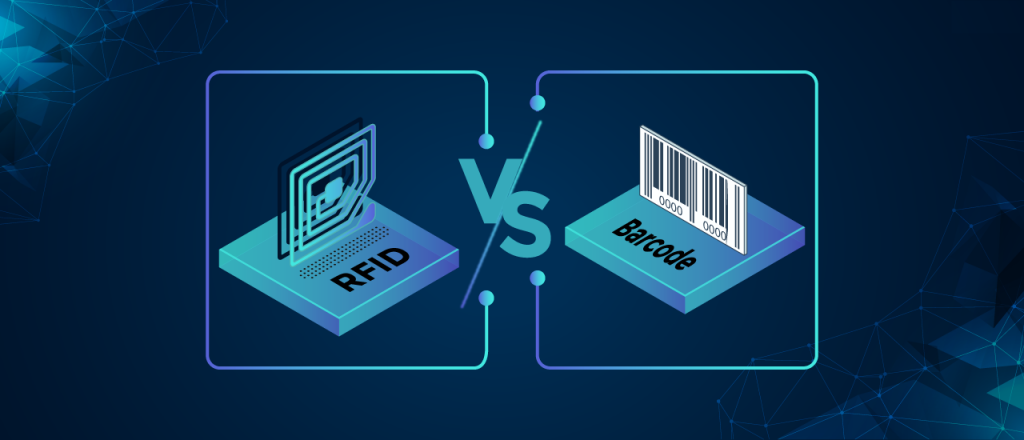

RFID and Barcode Comparison

RFID readers can read many tags at the same time. In barcodes, labels are read one by one. RFID tags allow much more data storage than barcodes. Their memory is much higher. RFID tags have dynamic storage memories that allow you to store even more data than when using barcodes.

RFID systems have both passive and active tags. Active tags have reading distances of up to 100 metres. Passive tags can transmit data to a reader up to 1 metre away. Barcodes, on the other hand, require an optical contact. They are read from much shorter distances compared to RFID tags. RFID tags are more resistant to environmental factors. Therefore, they have a much longer life compared to barcodes.

Challenges of RFID in the Textile Industry

A certain period of time is needed for the establishment of this system. It is necessary to supply the readers, position them correctly, supply the labels, code them correctly, complete the software process and ensure integration. In addition to this period, RFID technology is more costly than other systems. One of the biggest disadvantages is the high cost compared to other systems. RFID systems do not have major difficulties if the cost issue is overcome.

Labels: textile tracking, production tracking, rfid textile system

August 26, 2022

Return to List